Welding Services, Companies, and Training: A Practical Guide

Introduction

Welding quite literally holds our built world together. From structural frames in buildings and bridges to stainless tanks for food production and precision parts in medical devices, reliable welds are the quiet backbone of modern life. Whether you are a facility manager evaluating vendors, a small shop owner comparing processes, or a career‑seeker choosing a training path, understanding how services, companies, and education connect will help you make decisions that are safe, efficient, and cost‑conscious.

Outline

– Welding services: scope, deliverables, and where each process shines

– Evaluating welding companies: safety, qualifications, quality systems, and communication

– Process comparison: MIG, TIG, and stick—strengths, limitations, materials, and environments

– Pricing and project control: how estimates are built and how quality assurance reduces rework

– Training and careers: pathways, program selection, skill benchmarks, and long‑term growth

Welding Services: Scope, Deliverables, and Where They Fit

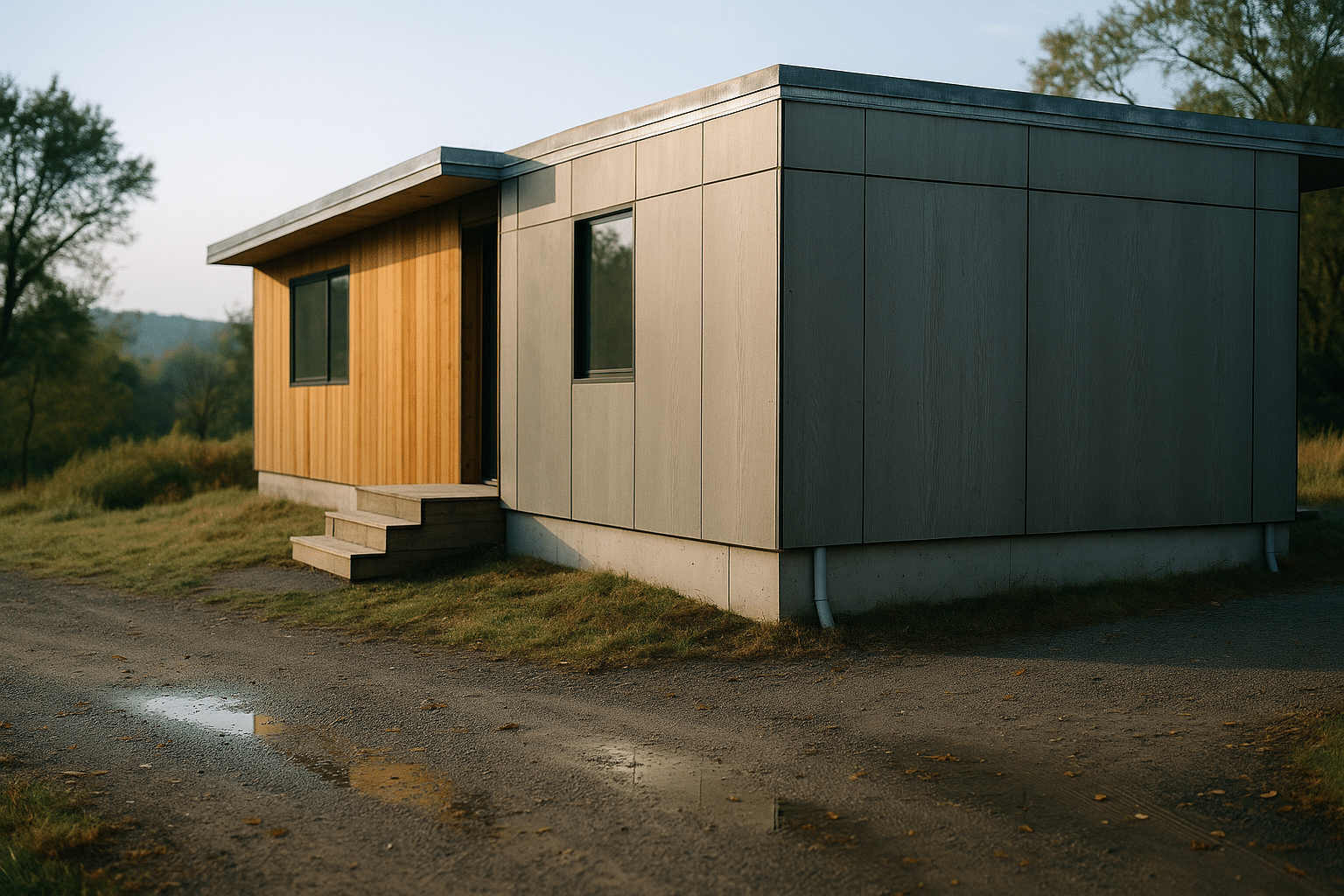

Welding services range from quick repairs to multi‑month fabrication projects. At one end, a mobile unit may restore a cracked hinge or patch a corroded handrail. At the other, a fabrication shop produces stair assemblies, pressure‑bearing components, or sanitary piping modules that must meet strict codes and pass inspections. The service you need depends on material type, thickness, environment, and performance requirements—factors that strongly influence cost and production speed.

Common processes include:

– Gas metal arc welding (often called MIG): fast, versatile on carbon steel and some stainless and aluminum, good for production in controlled environments.

– Gas tungsten arc welding (often called TIG): slower, precise, excellent control on thin materials, stainless, aluminum, and when a clean, refined bead is desired.

– Shielded metal arc welding (often called stick): rugged, portable, tolerant of less‑than‑ideal site conditions, widely used for field repairs and structural work.

– Flux‑cored arc welding: high deposition rates, productive for thicker sections and outdoor use with the right consumables.

Deliverables typically include a clear scope of work, material specifications, and a finish requirement. For example, a food‑grade tank repair might call for stainless filler metal, controlled heat input to limit distortion, and a crevice‑free surface for cleanability. A structural retrofit could require full‑penetration groove welds, position welding overhead or vertical, and verification by non‑destructive examination.

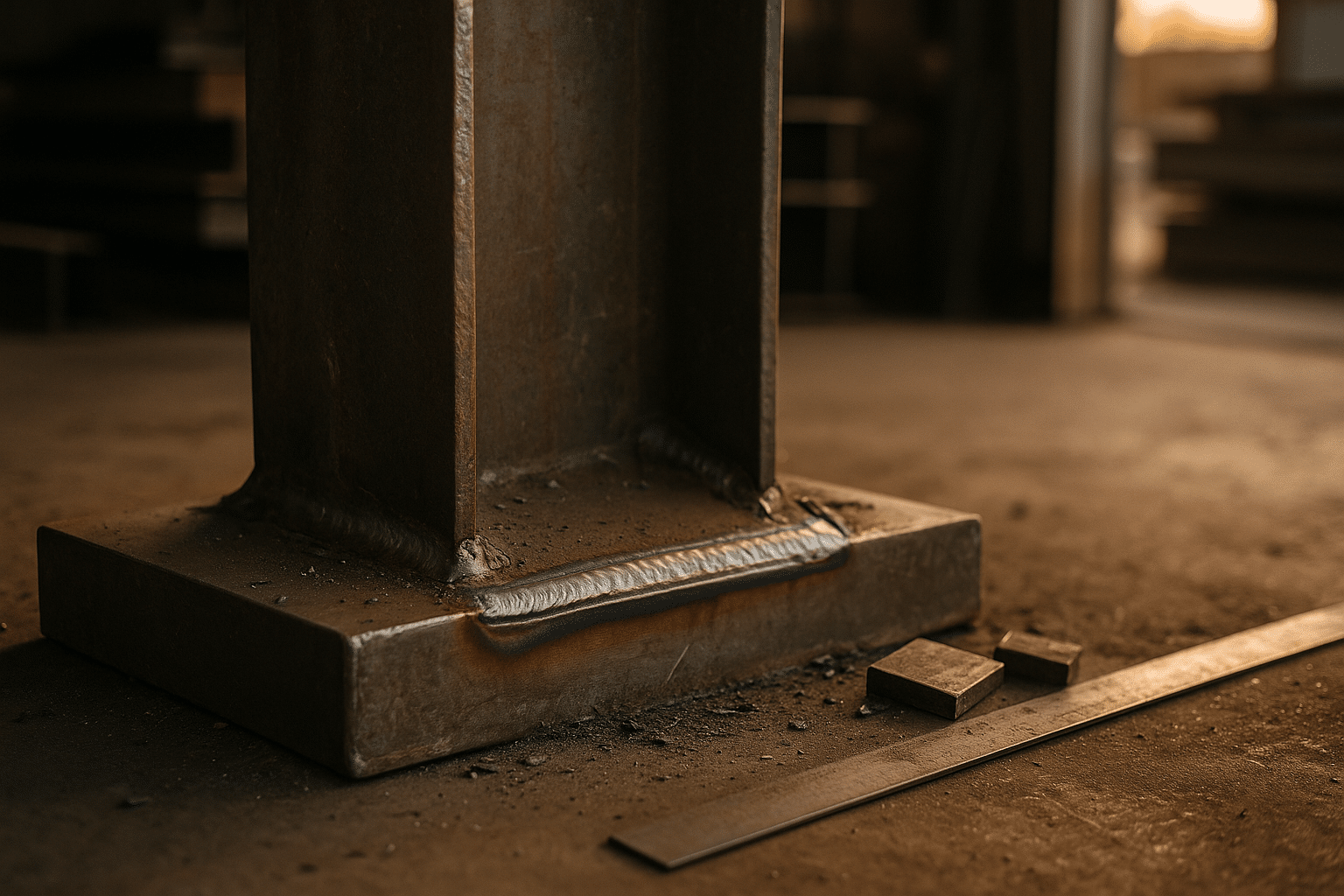

Safety and quality are inseparable from service. Responsible providers use written procedures, qualified welders, and testing where needed. Inspections may involve:

– Visual examination for contour, undercut, and discontinuities.

– Liquid penetrant or magnetic particle checks for surface‑breaking defects.

– Ultrasonic or radiographic methods for internal integrity on critical joints.

What does this mean for buyers? Match the process and provider to the environment and performance expectations. If you need speed and repeatability on carbon steel brackets in a shop setting, a wire‑fed process with fixtures may shorten lead time. If you need a neat, low‑spatter weld on thin stainless where aesthetics matter, a precision method is often worth the slower travel speed. When the work is outdoors or at height, portability and shielding considerations come first. The right pairing reduces rework, shortens schedules, and ultimately lowers total cost—even when the hourly rate looks higher on paper.

How to Evaluate Welding Companies: Safety, Qualifications, and Reliability

Choosing a welding company is a decision with safety and budget consequences. A polished website is not proof of capability. Look instead for evidence of a disciplined system: qualified people, documented procedures, and a culture that treats safety and quality as daily habits rather than occasional checkpoints. Reputable firms can explain their approach in plain language and back it with records.

Key indicators to review:

– Welder qualifications: Ask for current qualification records for the specific materials, thicknesses, and positions your project requires.

– Written procedures: Request representative welding procedure documents that specify joint prep, filler metal, shielding gas, electrical parameters, and acceptance criteria.

– Safety program: Look for job hazard analyses, lockout/tagout practices, fall‑protection planning, and fit‑for‑purpose ventilation. A company that opens with safety tends to plan the rest well.

– Material capability: Can they handle carbon steel, stainless, aluminum, and the thickness range you need? Do they have fixtures, positioners, and preheat equipment if your work demands it?

– Inspection readiness: Are they comfortable with visual and non‑destructive examinations, including scheduling third‑party inspectors when required?

Service reliability shows up in logistics and communication. Ask how they schedule shop versus field crews, manage lead times on filler metals and gases, and coordinate with other trades. For a small but telling test, note how promptly and clearly they respond to scope questions. Detailed proposals that spell out inclusions, exclusions, and assumptions reduce surprises later. Typical elements to expect:

– Drawings or sketches with joint details and tolerances.

– Surface preparation standards and post‑weld finishing expectations.

– Hold points for inspections prior to painting or insulation.

– A change‑order process that explains how added scope is priced.

Red flags include vague, flat‑rate quotes for complex work, reluctance to share qualifications, and dismissive attitudes about safety controls in challenging environments (confined spaces, elevated work, or weather‑exposed tasks). It is also reasonable to ask for references and photo evidence of similar projects—focusing on weld quality, cleanliness, and fit‑up, not just finished paint. A pragmatic selection method is to solicit two to three detailed proposals, interview each company, and choose the team that demonstrates technical fit and responsible planning, not simply the lowest price.

Process Comparison: MIG, TIG, and Stick—Strengths, Limitations, and Use Cases

Different welding processes trade speed for precision, portability for cleanliness, and deposition rate for control. Understanding these tradeoffs helps you choose the right approach for your part geometry, material, and environment.

Wire‑fed gas metal arc welding is a productivity workhorse. It offers steady wire feed, relatively low operator fatigue, and consistent bead shape—advantages for repetitive joints and medium‑thickness carbon steel. With proper setup, it can handle stainless and aluminum, though aluminum often benefits from specialized wire feeding and technique. It excels in shop settings with good shielding and fixtures. Limitations include sensitivity to wind (shielding gas can disperse) and potential for spatter if parameters drift or cleanliness is lacking.

Gas tungsten arc welding is the precision instrument of manual welding. A non‑consumable tungsten electrode and separate filler control let the operator fine‑tune heat and bead placement. The result is excellent for thin‑gauge stainless and aluminum, critical root passes, and aesthetic joints where a uniform “stacked” appearance matters. Tradeoffs are lower travel speed and higher labor hours. For short, high‑value welds or complex geometries, the quality payoff can outweigh the time cost. For long seams on thick plate, other processes usually win on schedule.

Shielded metal arc welding relies on flux‑coated electrodes that carry their own shielding, making it rugged in wind, rain, or tight spaces. It is common for structural steel erection, repair of heavy equipment, and field tie‑ins. Advantages include simple equipment and broad applicability across positions. Limitations involve more frequent stop‑starts, slag removal between passes, and a skill curve to manage arc length and heat input consistently. On thick sections, deposition rate is lower than flux‑cored options designed for high productivity.

A practical way to decide:

– Need speed on repetitive carbon steel in a shop? Wire‑fed methods are efficient and consistent.

– Need immaculate beads on thin stainless or aluminum? A precision method is appropriate.

– Working outdoors or in constrained access? A flux‑shielded rod process offers reliability.

Materials influence choice too. Carbon steel is forgiving and compatible with all three. Stainless demands cleanliness and controlled heat to preserve corrosion resistance; purge gas on the backside may be necessary for certain joints. Aluminum requires attention to oxide removal and often alternating current for arc stability in a precision process. Ultimately, the “right” process is the one that achieves the target properties and visual standards in the fewest total hours when you account for prep, welding, cleanup, and rework risk—not just arc‑on time.

Pricing, Quotes, and Quality Assurance: How Costs Are Built and Controlled

A welding quote is not a single number pulled from thin air; it is the sum of labor, materials, equipment, logistics, and quality control. Understanding these pieces helps you compare proposals fairly and manage your budget without compromising safety.

Typical cost drivers:

– Labor hours: Fit‑up, tack, root pass, fill and cap, interpass cleaning, and final finishing. Position (overhead vs. flat) and access constraints increase time.

– Consumables: Filler metals, shielding gas, electrodes, grinding discs, and brushes. Specialty alloys and purging supplies raise cost.

– Equipment and tooling: Positioners, preheat gear, power needs, and sometimes rental charges for lifts or generators for remote work.

– Mobilization and travel: Site visits, setup time, and mileage or per‑diem for field crews.

– Inspection and testing: Visual checks, surface examinations, and internal integrity tests where required.

To illustrate, consider a hypothetical 20‑piece bracket run in a shop setting. The fabricator estimates two hours per piece for cutting, prep, and welding, plus four hours total for fixturing and a final hour for inspection and packaging. Consumables are priced per piece, with a contingency for rework. If shop labor is billed at a mid‑range hourly rate and materials are common grades, the final price reflects both volume efficiency (fixtures pay off after the first few parts) and quality controls that reduce scrap. For field tasks, expect higher hourly rates reflecting travel, setup, and the tougher conditions that slow production.

Quality assurance saves money by preventing rework. Specify acceptance criteria up front: allowable visual discontinuities, weld sizes, tolerances, and any tests. Insist on hold points where inspectors verify fit‑up before weld, and before coatings or insulation conceal joints. A concise inspection plan can include:

– Verification of joint preparation and cleanliness.

– Parameter checks at the start of shifts or runs.

– Documentation of welder continuity on the specific procedures used.

– Non‑destructive examination for critical welds with defined acceptance standards.

Comparing quotes fairly means aligning scope. Ask vendors to list assumptions: Are they including material procurement? Who handles surface prep, painting, or post‑weld machining? What environmental conditions are assumed for field work? A clear scope prevents low initial numbers that grow through change orders. The most economical choice is often the team that invests time in clarifying details early, proposes fixtures or sequence changes that reduce labor, and demonstrates how their quality plan lowers lifecycle cost—not necessarily the lowest initial price.

Training and Careers in Welding: Pathways, Program Selection, and Long‑Term Growth

Welding careers offer hands‑on problem solving, visible results, and diverse workplaces—from quiet fabrication bays to wind‑swept job sites. Training routes vary, but successful paths share three elements: structured practice, safety habits, and progressive challenges that build from fundamentals to specialized work.

Common training pathways:

– Short‑form certificates: Focused programs that cover safety, joint prep, and core processes. Many learners complete foundational training in several months and are job‑ready for entry‑level roles with supervision.

– Apprenticeships: Earn‑while‑you‑learn models that combine paid work with classroom instruction over multiple years, leading to broad capability in fabrication, layout, and code‑compliant welding.

– Advanced endorsements: Targeted modules for stainless sanitary welding, aluminum fabrication, pipe position work, or testing methods, taken after mastering the basics.

What to look for in a program:

– Instructor experience and student‑to‑booth ratios that allow regular feedback.

– Curriculum that includes print reading, measurement, metallurgy basics, and process theory—not just hood‑time.

– Safety integration: Respiratory protection for fumes, ventilation, fire watch practices, and ergonomics for grinding and layout.

– Objective skill checks: Fillet break tests, guided bends, and visually inspected groove welds in multiple positions.

Costs vary by region and program length, but thoughtful budgeting considers tuition, personal protective equipment, and consumables. Many learners assemble a starter kit (helmet, gloves, jacket, and basic hand tools) and then build up with specialty items as they advance. While some candidates find entry‑level roles within months, higher earnings usually align with proven reliability: showing up prepared, following procedures, documenting work, and learning to read jobs beyond the puddle—fit‑up, sequence, distortion control, and inspection readiness.

For employers, supporting training pays back through fewer defects and safer job sites. Consider tuition assistance tied to milestones, cross‑training across processes, and mentorship where seasoned welders coach on arc control and problem diagnosis. For career‑seekers, set milestones: flat and horizontal joints on carbon steel, then vertical and overhead, then stainless control, and finally aluminum or pipe with open roots. Keep a portfolio of macro‑etched samples and photos of fixtures and assemblies you’ve produced—these demonstrate an understanding of quality and repeatability.

Conclusion for buyers and learners: Plan deliberately. Buyers should select providers that show their work—procedures, qualifications, and safety planning—because consistent quality protects both budgets and people. Learners should pick programs that balance theory, practice, and safety, then commit to steady improvement. In both cases, progress is forged by preparation: measure carefully, protect the team, document the work, and the results will be strong enough to carry their own weight—today and years from now.