Modular Homes

Outline and How to Use This Guide

Modular homes have moved from niche to mainstream, offering a practical route to ownership with shorter timelines and predictable quality. Before comparing listings, it helps to map the journey: understanding what modular construction is, where to find credible homes for sale, how to evaluate sustainable features, and how to select a builder whose craftsmanship and service record align with your expectations. This guide follows that path. First, we clarify terms and set expectations. Next, we scan the market for modular homes for sale, including price patterns, common layouts, and delivery considerations. We then dive into affordability and sustainability, translating energy and material choices into monthly cost implications. After that, we outline a step-by-step process for finding top-rated modular home builders near you, with questions to ask and red flags to avoid. Finally, we end with a concise action plan and conclusion tailored to first-time buyers and seasoned homeowners alike.

Think of this outline as your map:

– Part 1: Definitions, scope, and what makes modular distinct from manufactured and site-built options

– Part 2: Market snapshot of modular homes for sale, typical price ranges, and how listings are structured

– Part 3: Affordable, sustainable configurations and which upgrades pay back over time

– Part 4: How to evaluate local builders, compare quotes, and verify credentials

– Part 5: A purchase checklist and timeline that keeps your project on track

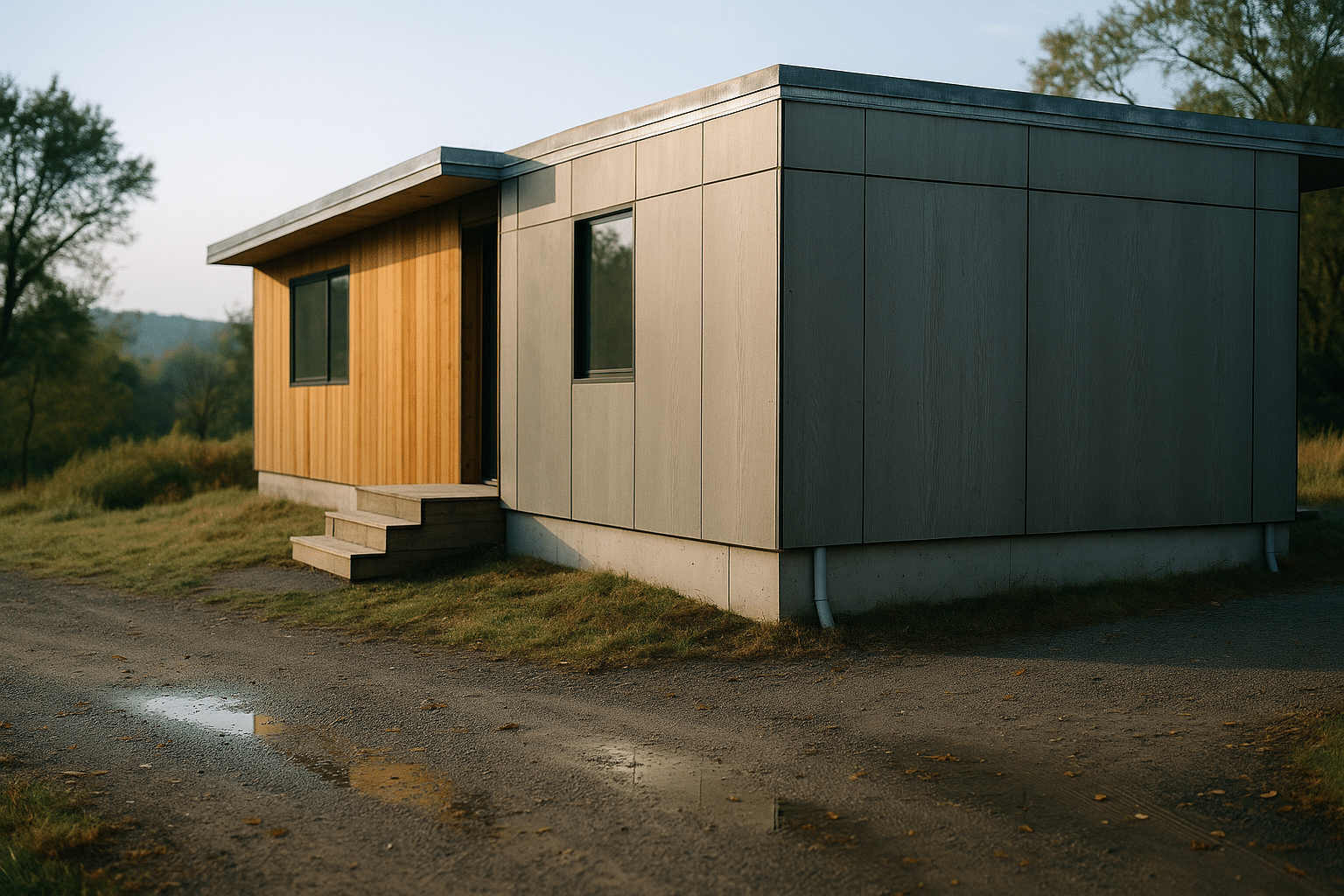

Why structure matters: modular projects succeed when the buyer aligns expectations with logistics. Modules are built off-site in a controlled environment, then transported and set on a prepared foundation. That means early decisions about site access, permitting, and financing can prevent costly delays down the line. It also means quality control is often more consistent than purely site-built processes, because the same crews assemble similar components under repeatable conditions. At the same time, the advantages of predictability and speed only show up fully when you choose an experienced builder and plan for utility connections, inspections, and local code compliance. Use this outline to keep your focus: understand the product, vet the seller, sharpen the budget, and coordinate the final mile from factory to front door.

Modular Homes for Sale: Market Overview, Pricing, and What Listings Don’t Tell You

Shopping for modular homes for sale feels different from browsing conventional listings, because you’re often buying a factory-built product plus a service package for transport, set, and finishing. The headline price may include the modules and standard finishes, while site work, foundation, utility hookups, permits, taxes, and delivery can be priced separately. To compare apples to apples, request an itemized quote that distinguishes the home shell, interior finishes, and all site-related costs. In many regions, turnkey modular pricing commonly falls within a broad spectrum such as approximately $140–$260 per interior square foot, influenced by location, design complexity, and finish levels. Rural sites with challenging access or rocky soils can shift costs upward, while compact footprints and simple rooflines can contain them.

Timeline is another differentiator. Factory production typically spans 6–12 weeks once final drawings are approved, followed by transport, crane set, and on-site finish work that may add 4–10 weeks depending on weather and inspections. Compared with many site-built schedules, this can compress overall delivery by several months, especially in markets with skilled labor shortages. Appraisals generally rely on comparable sales of similar homes and may require the lender to review modular-specific documentation, such as the state approval label and engineered plans. Inspections follow local building codes, just as with site-built homes; modules must meet or exceed the code requirements for the jurisdiction where the home will be placed.

Listings often highlight flexible floor plans: ranch layouts for accessibility, two-story designs for small lots, and accessory dwellings for multigenerational living or rental income. Common upgrade categories include enhanced insulation packages, air-sealing details, durable flooring, and solid-surface counters. Buyers focused on long-term value frequently prioritize envelope performance and mechanical systems over purely cosmetic features, because those choices influence energy spend and comfort every day. Pay attention to delivery lead times in fast-moving markets: high demand can extend factory slots, so reserving a production window early can be prudent.

To shop listings efficiently, prepare a one-page worksheet that captures: target square footage, bedrooms/baths, roof style, mechanical preferences, intended certification goals (if any), and a ceiling budget for site work. Ask the seller to confirm transportation distance and whether pilot cars or special routing could add fees. Finally, clarify what is “by owner” versus “by builder” at closing, such as landscaping, driveways, and appliances. Tight, transparent scopes lead to smoother move-in days and fewer surprises when the modules arrive on site.

Affordable, Sustainable Modular Homes: Features That Lower Bills and Raise Comfort

Affordability in modular housing is not just about the purchase price; it is also about monthly operating costs and durability. Sustainable features can shrink utility bills, stabilize indoor comfort, and protect against energy price volatility. Because modules are produced in a controlled setting, precision framing and repeatable air-sealing details are easier to achieve, which supports strong energy performance. For buyers seeking value, a practical approach is to invest first in the building envelope and right-size the mechanical systems, then add finish upgrades as budget allows.

Energy and envelope strategies commonly available include:

– Higher R-value wall and roof assemblies with continuous exterior insulation

– Careful air-sealing at seams between modules and around penetrations

– High-performance windows with low solar heat gain coatings tailored to climate

– Ducted or ductless heat pumps and smart controls to match part-load conditions

– Heat-pump water heaters or efficient on-demand systems

– Heat recovery ventilation to maintain fresh air without large energy penalties

These features can reduce heating and cooling loads substantially, which in turn allows smaller, less expensive equipment. In many climates, buyers report typical energy savings compared with entry-level code construction, though actual results vary with occupant behavior, weather, and local utility rates. Water efficiency is another quiet win: low-flow fixtures, insulated hot water lines, and drain-water heat recovery can trim both water and energy use. For materials, look for low-emitting finishes, sustainably harvested wood, recycled steel options, and tile or flooring that balances durability with maintenance ease. Some buyers also ask for solar-ready electrical layouts, roof load detailing for future arrays, and conduit paths that simplify later installations.

Cost-wise, enhanced efficiency packages may add a modest percentage to upfront price but often recoup through lower monthly bills over a few years. A simple payback example: an added $6,000 envelope and mechanical upgrade that saves roughly $70 per month could cross breakeven in under eight years, while continuing to deliver comfort and resilience for decades. Not all green features have the same return, so prioritize items with measurable impact. Good candidates are airtightness targets, increased insulation thickness, and heat pumps sized to the actual load. Certifications from recognized third-party programs can validate performance claims and may qualify your project for local incentives, though requirements differ by region.

Sustainability also extends to construction waste and logistics. Factory workflows generate fewer offcuts, and leftover materials can be redeployed to the next build. Shorter on-site timelines mean less disturbance to neighbors and fewer weather-related delays. All told, an affordable, sustainable modular home balances design restraint with high-impact upgrades, creating a home that feels calm, quiet, and economical to operate without stretching the budget.

Top-Rated Modular Home Builders Near You: How to Evaluate, Compare, and Choose

Finding top-rated modular home builders near you starts with verifying licensing and experience, then drilling into process, pricing, and communication. A reliable builder will welcome specific questions and provide documentation without hesitation. Begin with the basics: confirm state modular approvals, contractor licenses, and insurance coverage. Ask how many projects the team delivers annually and whether your design is routine for their factory partners. Request recent client references and, if possible, visit a completed home to observe fit, finishes, and attention to detail at module seams and roof connections.

Quality and service are best judged by transparency. Insist on an itemized scope that distinguishes: factory specifications, on-site scope (foundation, set, finish), utility work, and third-party fees such as permits, engineering, and inspections. Clarify who manages each step, from final design drawings to transport scheduling. A well-regarded builder typically provides a timeline with critical milestones, including design freeze, production slot, delivery date range, set day, and punch list. Clear change-order procedures matter: you should know when changes are cut off by the factory and how costs are calculated if you adjust finishes late in the process.

Use this checklist during interviews:

– Portfolio relevance: examples close to your size, style, and climate

– Factory alignment: partner facilities with proven output and consistent quality control

– Warranty terms: structure, systems, and finish coverage spelled out in writing

– Communication rhythm: weekly updates and a single point of contact

– Site-readiness plan: surveys, soil reports, and access route confirmations

– Safety and logistics: crane coordination, staging areas, and neighborhood notifications

Compare proposals not just on price but on assumptions. One builder may include a full set-and-finish package, while another expects you to hire trades for mechanicals and final trim. Small omissions can become large cost variance later, so align every line item. Ask to see a sample closeout packet that includes manuals, warranties, and compliance documents—this indicates how the builder will support you after move-in. If you can tour the factory, observe moisture control, material storage, and station-by-station inspection steps; repeatable quality typically correlates with tidy workflows and skilled crews. Finally, read local reviews with a discerning eye: consistent praise for schedule adherence and punch-list responsiveness is often more meaningful than isolated comments about minor finish preferences.

The right builder is a partner who explains constraints plainly, offers solutions early, and steers you away from unnecessary complexity. With a structured interview process and thorough proposal comparisons, you can select a team that delivers both craftsmanship and steady guidance from design to occupancy.

Conclusion: Your Path to a Future-Ready Modular Home

Stepping into modular home ownership is as much about planning as it is about product selection. The market offers a wide range of modular homes for sale, from compact layouts suited to urban lots to spacious multi-module configurations for open sites. By approaching the search with a clear scope—size, budget, performance goals—you turn a sprawling set of options into a focused, achievable plan. Affordability and sustainability align when you prioritize the building envelope and right-size the mechanicals; this keeps monthly costs predictable while boosting comfort year-round. The builder you choose makes the plan real, so invest time in interviews, references, and scope alignment before you lock in a production slot.

Use this concise action plan to move forward with clarity:

– Define needs: bedrooms, baths, storage, accessibility, and future expansion ideas

– Set performance targets: energy use, indoor air quality, and solar readiness

– Establish a realistic budget: separate home price from site work and soft costs

– Pre-qualify financing: confirm lender familiarity with modular documentation

– Shortlist builders: verify licenses, insurance, references, and sample schedules

– Compare itemized proposals: confirm inclusions, exclusions, and allowances

– Secure site logistics: survey, soil test, access route, and utility coordination

– Lock timeline: design freeze, factory slot, delivery window, and set day plans

Expect some variability—weather, inspection timing, and supply conditions can shift schedules. The advantage of modular lies in its controlled production and predictable quality, provided that early decisions are documented and responsibilities are clear. If a feature must flex to stay on budget, simplify shapes and finishes before trimming core performance; your future self will appreciate the quieter, more efficient home. As you assemble your team and refine your design, keep the end experience in mind: a home that arrives with precision, settles onto a prepared foundation, and welcomes you with steady temperatures, clean air, and a layout that fits your life. With preparation and the right partners, modular can offer a smooth path from research to move-in—measured in weeks of production rather than seasons of delays, and defined by choices that support comfort, durability, and long-term value.